Home / Final Drives

Final Drives

EXCAVATOR FINAL DRIVES

The final drive of an excavator refers to the transmission system that transmits the power generated by the engine to working devices such as crawler tracks and bucket rods to achieve excavation operations. Through the transmission system, the excavator can travel and turn, and can also realize functions such as up and down rotation of the arm and telescopic insertion of the arm.

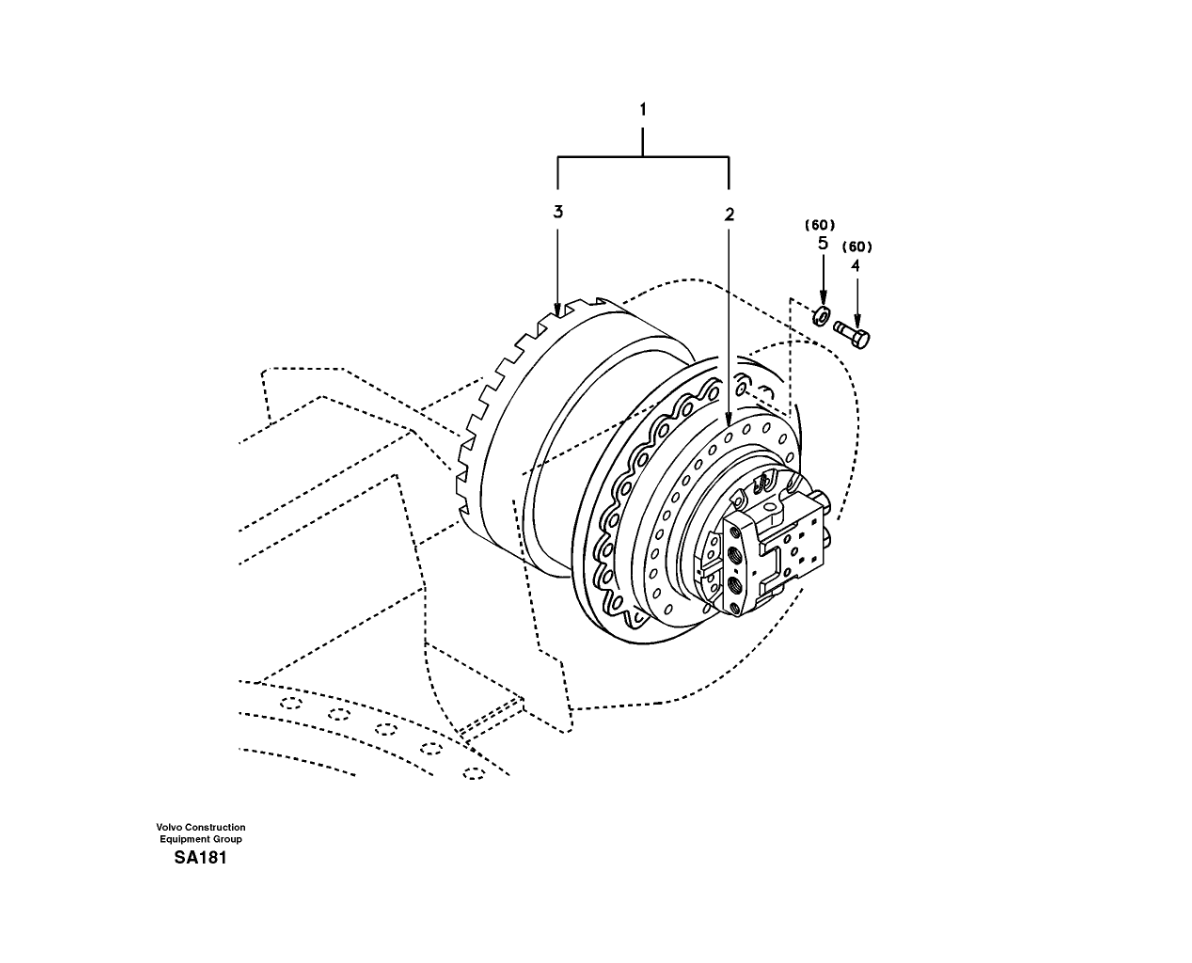

Final Drive Structure

The final drive is also called the traveling assembly or the driving wheel. The final drive consists of two parts: the hydraulic motor and the swing reduction gearbox. The hydraulic motor is an actuator of the hydraulic system, which converts the liquid pressure energy provided by the hydraulic pump into the mechanical energy (torque and rotational speed) of its output shaft.The reduction gearbox is a power transmission mechanism that uses a gear speed converter to reduce the number of revolutions of the motor to the required number of revolutions and obtain a larger torque. There are two final drives on the left and right tracks of the excavator, which directly drive the tracks to enable the machine to move forward, reverse and turn.

Concepts & Features

1. High efficiency and energy saving: Because the final drive needs to transmit power through the gearbox and hydraulic system, the engine speed can be reduced to the speed range most suitable for the workload, improving fuel utilization and achieving energy saving effects.

2. Precise control: The final drive of the excavator can automatically adjust the speed and torque according to the size of the workload, thereby achieving precise control of the excavating device.

3. Stable and reliable: The final drive system has the characteristics of smooth power transmission, smooth start, fast response and smooth operation, which can ensure the stable and reliable operation of the excavator.

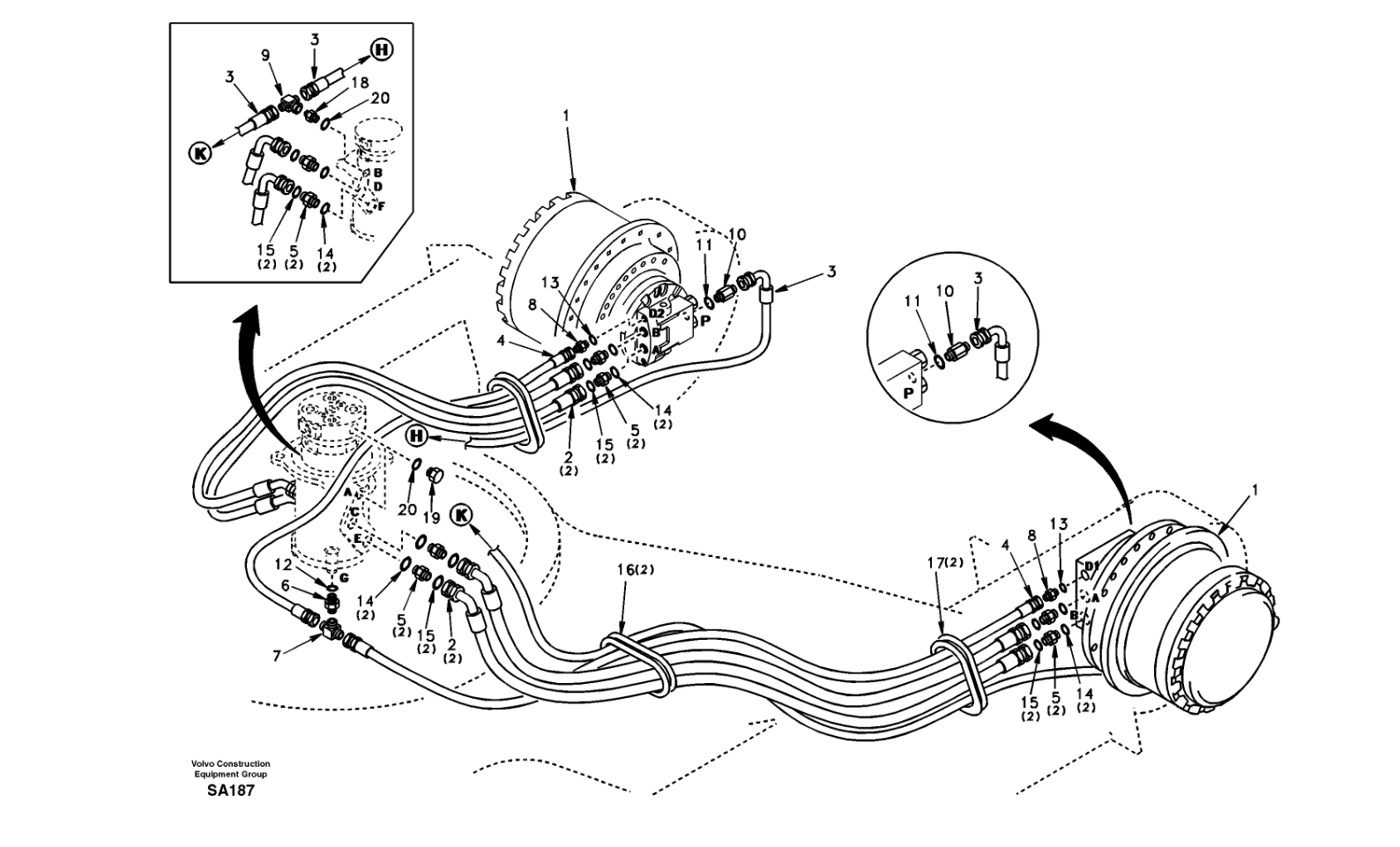

Traveling Power Transmission Route

Diesel engine - Coupling - Hydraulic pump (mechanical energy converted into hydraulic energy) - Distribution valve - Central rotary joint - Traveling motor (hydraulic energy converted into mechanical energy) - Reduction gearbox - Drive wheel ——Rail chain crawler——Achieving walking

Hydraulic drive is the current mainstream excavator travel drive. This method mainly uses the function of the hydraulic system to convert the engine's power output into hydraulic energy, and then converts the energy into mechanical energy through the hydraulic motor to realize the walking of the vehicle.

Hydraulic drive has the following advantages:

1. Large torque and low speed walking. These two features improve the excavator's ability to pass and work on slopes, mud and other road conditions;

2. High accuracy. The hydraulic system itself can achieve fine adjustment of energy output, and can accurately accelerate and decelerate as needed, improving the operator's controllability.

3. High flexibility. Different brands, models, and excavator parameters vary greatly. Through the hydraulic system, the hydraulic system can be flexibly designed according to the different needs of the excavator.

Copyright © 2025 Guangzhou Hansi Hydraulic Machinery Co.,Ltd. Support By BEE Cloud